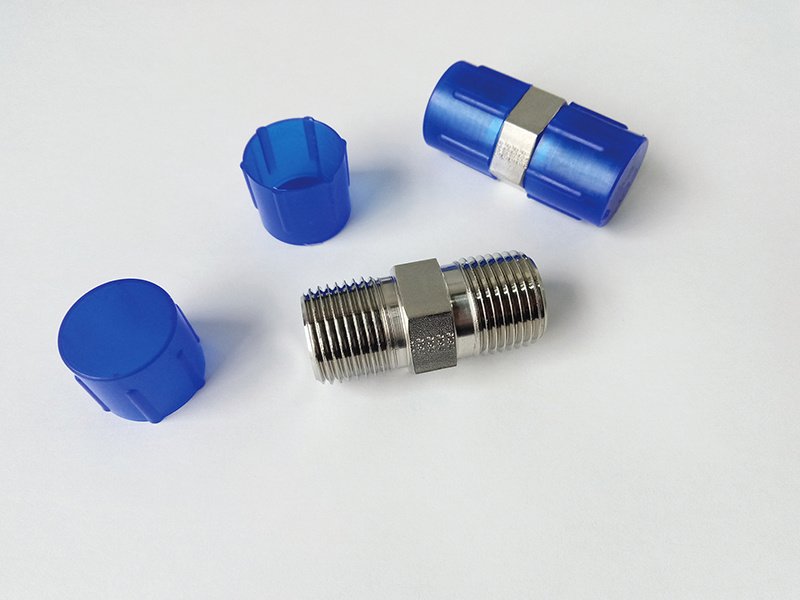

Principle of flare fittings

Flared fittings, the receiver (generally copper or thin-walled steel tube) end of the Xieng Khouang mouth angle of 74

Flared fittings, the receiver (generally copper or thin-walled steel tube) end of the Xieng Khouang mouth angle of 74 ., the guide sleeve of the inner taper hole is 66 . Assembly of the tightening force through the nut into an axial compression force, by the guide sleeve to take over the flare part of the mouth, so that the flare cone and the joint body sealing cone between the contact pressure. In the rigid sealing at the same time, play a role in connecting and bear by the tube fluid pressure generated by the joint body and the axial force between the receiver.

Because the sealing performance of the flare type pipe joint depends on the geometric accuracy of the flare cone and the appropriate assembly tightening force to be ensured, so it is difficult to realize the high-pressure sealing, the general working pressure is less than 16MPa. flare type pipe joint types and specifications see GB5625.1-1985 ~ GB5652-1985.

Related News