Principle of Welded Fittings

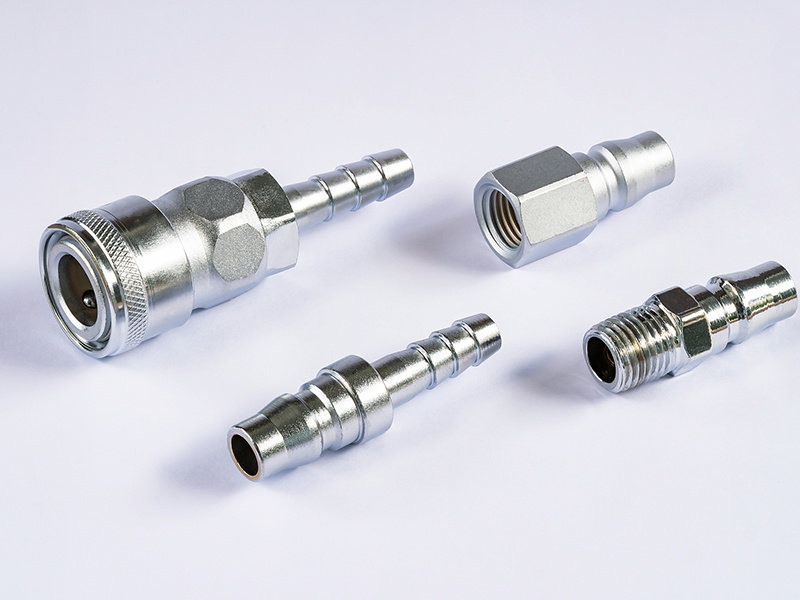

Pipe fittings are used for the connection between pipes and pipes or pipes and hydraulic components

Pipe fittings are used for the connection between pipes and pipes or pipes and hydraulic components, and the main requirements for pipe fittings are easy installation and disassembly, vibration resistance and good sealing performance.

Currently used for hard pipe connection of the main types of pipe fittings welded, flared, ferrule type pipe fittings.

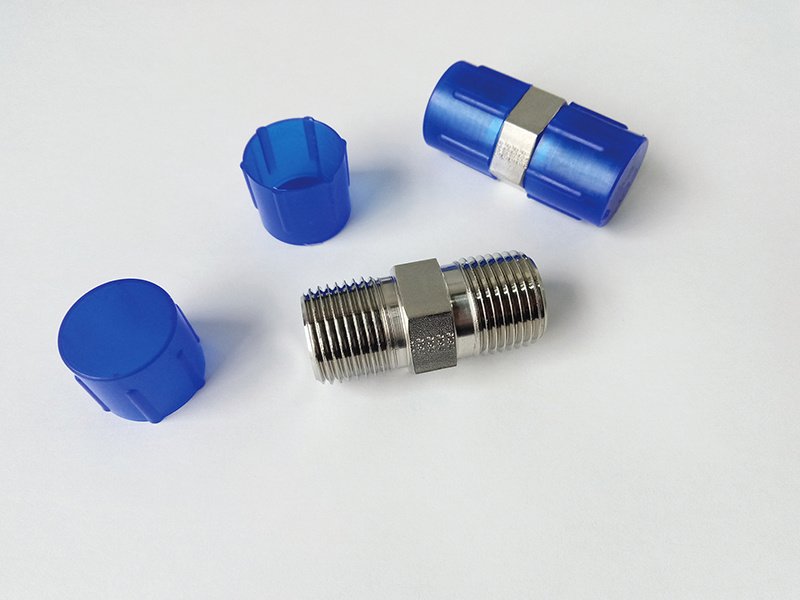

1, welded pipe joints

Welded fittings are mainly composed of joint body, nut and receiver, etc., the screwed-in end of the joint body for the fine tooth pipe thread, the joint surface should be added to the combination of gaskets, if the screwed-in end of the conical thread, it is not necessary to install the combination of gaskets. Joint body and take over with O-ring seal, take over by the nut pressed tightly in the joint body end face, its outer end and steel pipe welding connected.

Welded pipe joint structure is simple, easy to manufacture, high pressure resistance (32MPa), good sealing performance. The disadvantage is that the welding quality of the steel pipe and the receiver requires high quality.

Welded pipe joints joint body and nut material is generally 35 or 45 steel, welded pipe for 15 or 20 steel. In order to ensure the quality of welding, the steel pipe connected to it should be selected with ordinary grade precision 15 or 20 cold-rolled (cold-rolled) seamless steel pipe. If the working medium is corrosive medium, the material should be selected stainless steel. In order to meet the different requirements of the hydraulic system pipe connection, welded pipe fittings are divided into end straight pipe fittings, straight pipe fittings, tee pipe fittings, four-way pipe fittings, next door straight pipe fittings and manifold fittings and other types, the selection of reference to the relevant standards (JB966 -1002-77) or product samples.

Related News