Assembly of Tube Fittings

The most important part of the pre-assembly of the tube fitting, which directly affects the reliability of the seal.

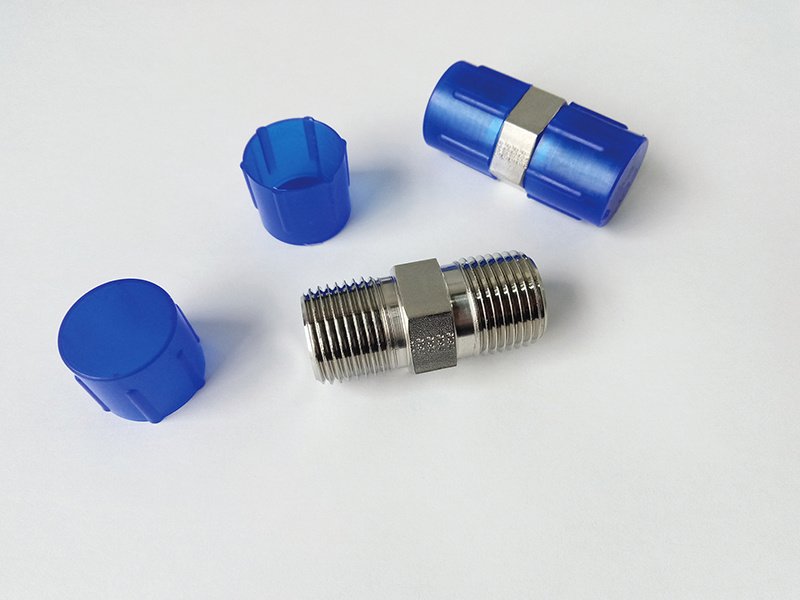

(A) Pre-assembly ① The most important part of the pre-assembly of the tube fitting, which directly affects the reliability of the seal. Generally need a special preloader. Small diameter fittings can be pre-assembled in a vise. Specific practice is to use a fitting as a female body, the nut, ferrule compression to the tube can be. There are mainly ferrule type straight-through fittings, ferrule type end straight-through connectors, ferrule type tee fittings and other types. I found that, even if the same manufacturer a batch of goods, these types of joints on the body of the tapered hole depth is often not the same, the result is caused by leakage, and this problem is often ignored. The correct approach is that one end of the tube with what kind of joint body connection, the corresponding end of the connection with the same type of joint pre-installed, which can maximize the avoidance of leakage problems. ② Pipe ends should be flush. After sawing, the pipe should be sanded flush on a wheel or other tool, and burrs should be removed, cleaned, and blown out with high-pressure air before use. ③When preassembling, try to keep the coaxiality of the tube and the joint body, if the tube deflection is too large, it will also cause seal failure. ④ The preloading force should not be too large so that the inner edge of the ferrule is just embedded in the outer wall of the tube, and the ferrule should not be obviously deformed. In the pipeline connection, and then according to the specified tightening force assembly. ф6-1 ferrule tightening force for 64-1 15n, 16фmmr 259n, ф18mm for 450n. If the ferrule deformation is serious in the pre-installation, it will lose the sealing effect. (ii). It is prohibited to add fillers such as sealant. Some people apply sealant on the ferrule in order to obtain better sealing effect, and as a result, the sealant is washed into the hydraulic system, resulting in failures such as clogging of the yinny holes of the hydraulic components. (iii). When connecting the piping, the tubing should have enough deformation margin to avoid subjecting the tubing to tensile forces. (iv). When connecting the piping, avoid subjecting it to lateral force, which will cause poor sealing. (v). When connecting the pipeline, it should be good at one time and avoid disassembling it for many times, otherwise it will also make the sealing performance deteriorate. Tube fitting installation (1) according to the requirements of Chapter 9 on the need for pickling of the tube should be first pickling treatment; (2) according to the required length of the saw or special pipe cutting machine and other machinery to cut off the tube, absolutely not allowed to dissolve the break (such as flame cutting) or abrasive wheel cutting; remove the tube end of the inner and outer round burrs, metal swarf and dirt; remove the tube fitting rust inhibitor and dirt; but also to ensure that the roundness of the tube; (3) will be the nut, ferrule Successively set the nut and ferrule into the tube, the front edge of the ferrule (small diameter end) is at least 3mm from the mouth of the tube, and then insert the tube into the tapered hole in the body of the connector, and top it until it reaches the top; (4) Slowly tighten the nut, and at the same time, turn the tube until it does not move, and then tighten the nut by 2/3 to 4/3 turns; (5) Disassemble and check if the ferrule has been cut into the tube, and whether the position is correct. The ferrule is not allowed to have axial movement, and can be slightly rotated; (6) re-tighten the nut after passing the inspection.

Related News